MVVVA

MVVVA is a fruit bowl made for expressive people, eccentric and open to change, who are willing to practice these aspects in a process of disruption through its modularity, which allows it to be made through the assembly of its components, which by relating to the nature of the fruits stored in it, enhance them through contrast.

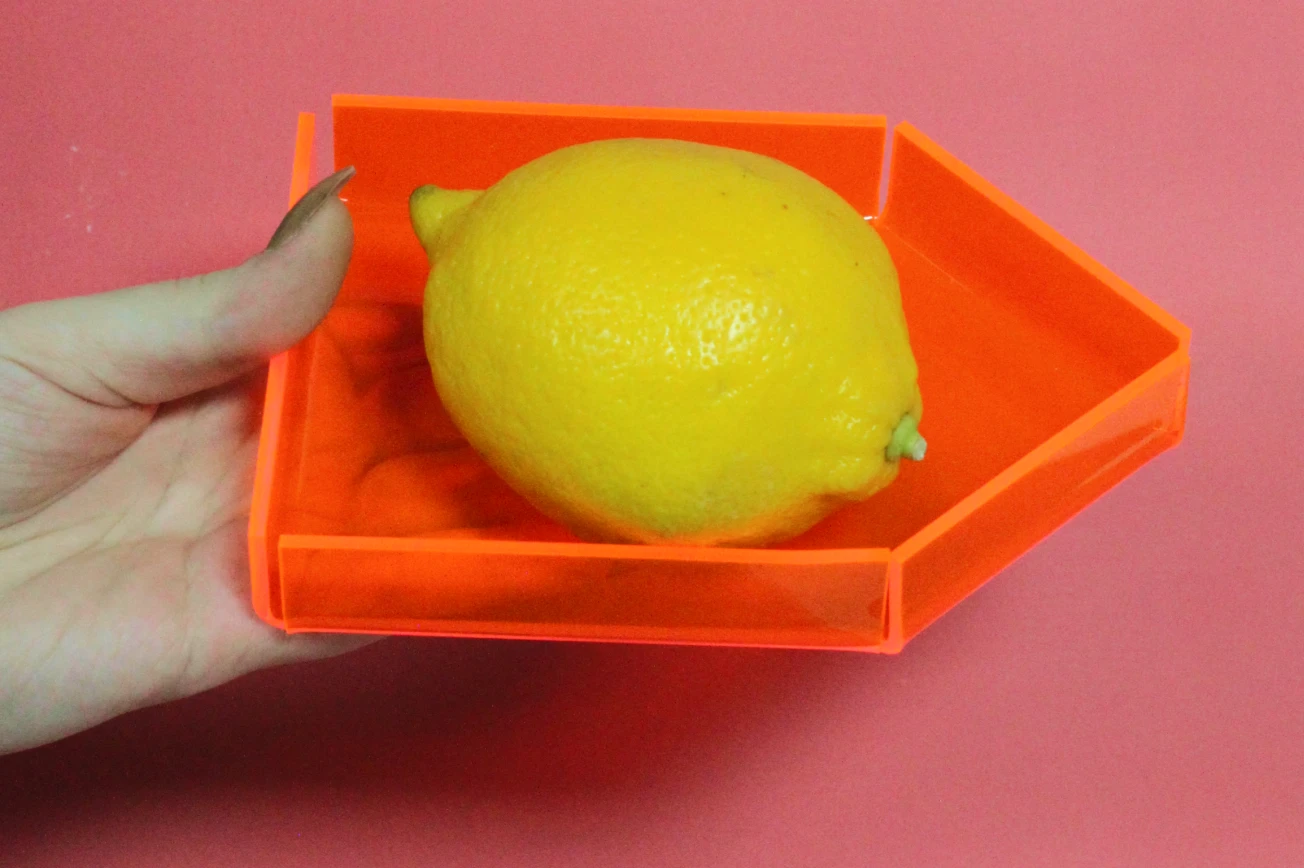

The first mockup testing of the project using fake fruits and carboard

The first mockup testing of the project using fake fruits and carboard

Briefing

Project made for the lecture of "Visual Methodology" in 12 weeks with Erika Schaiblich, Pedro Morais to pursue Bacharelor Degree in Product Design at Universidade Federal do Paraná

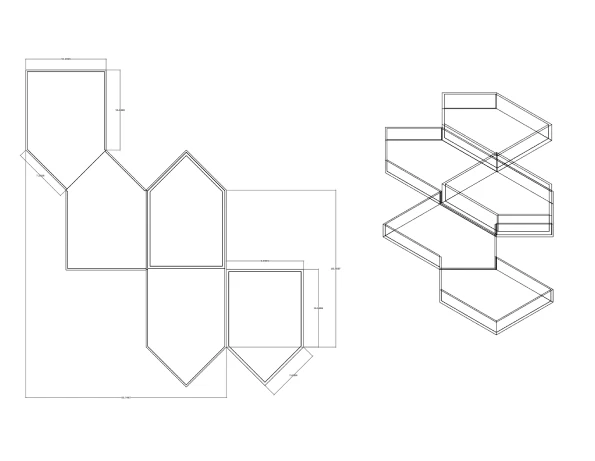

The briefing was to design a fruit basket that could hold 5 fruits, made of only one material and the construction had to be done with laser cutting or by CNC Machine.

All other aspects should be decided and planned by the team, as should the requirements selection.

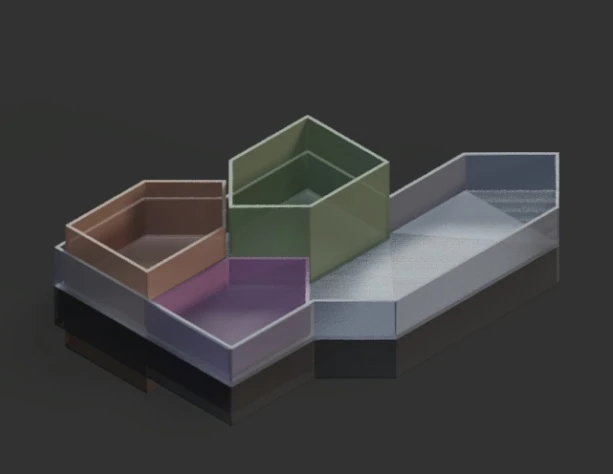

Acrylic sheets were one of the first selections. Perfect for color overlay.

Just like Olafur Eliasson's famous exhibition "Your Body of Work", the transparency of the colors allowed the environment to interact with the material.

The product reflects the experiments of the process of design

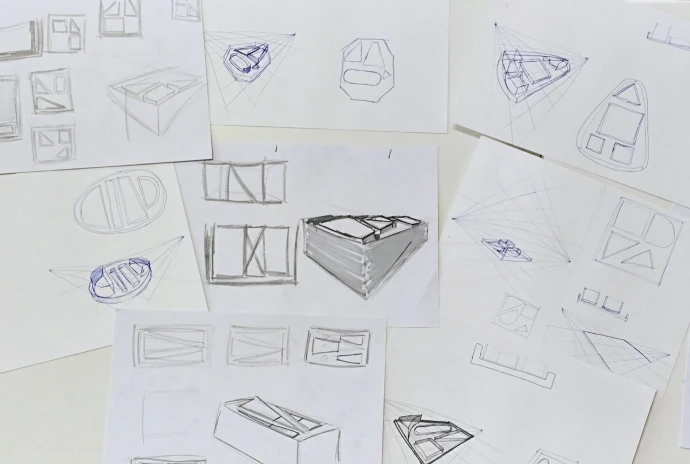

Imagining, skecthing, building the mock-up, at every moment the team experimented different compositions, instead of choosing one, the team decides to incorporate these changes into the final design.

Cutting costs

We had already decided all the specifics with different widths,sizes and colors: A big green, medium orange and small pink prism inside a blue base. We were also super excited to see the product taking shape in rendering softwares. The next step was ordering a specialist to laser-cut the fold board.

But, we weren't prepared for the cost.

Me and my teammate, Erika, then took a few rounds of alternatives development and feedback on how much that would cost. Meanwhile, we were trying to do more market research to change our supplier.

That's when we found a new one, that would do our new alternative for 50% of the price. With the design adapted we were ready to move on...

...And, they didn't have the colors

Back for a quick iteration.

From lemons to apples, fruits to appetizers, bowl to decoration. Use MVVVA for anything, the product changes as you do.

Final design

In its plastic structure coming from its translucent acrylic aspect allows the various interpretations, blending into the environment through its colors and defined edges, perfect for an urban, multicultural and dynamic environment

From its use in modern kitchens to decoration on shelves, from a repository to an ornament, the object not only dialogues with its multiple compositions, but also relates to storing any elements.

Other deliverables

The project had a strong sense of identity, with the team discovering how to express themselves through the concepts, if you want to explore more about the project here is some of the moodboards and a zine.

03 release KPIs

Even thought this is one of my favorite projects, I don't plan to it to be more than a university project. But if we were release it to the market that's 3 KPIs to be aware of:

Sales per Salespoint

Instead of Sales per REP, I prefer Sales per Salespoint as the KPI name. Using acrylic, a more affordable material, I aim to increase distribution. With its wide front, Sales per Salespoint will track total and unit sales accurately.

COGS

The Cost of Goods Sold will help the team keep track the costs when shaping the raw material into the product. As mentioned, even in a cheap material like acrylic, the cost from supplier to supplier can change a lot.

Average Selling Price

Not only the cost of product can vary, but with a wide distribution of the product, the price of it can change from sales point to another, the Average Selling Price will help the team making the more precise estimations around any other sales KPI.

I wish I knew

This is one of my favorite projects, most because of its aesthetic, however there's a lot of fining tuning i would like to do if I were to do it again.

Studying more about acrylic folding

I wouldn't say that, but you can see that this project has a little whoopsie- an empty space in the ridge that was overlooked during the 3D modeling process. This is the first thing that needs to be fixed.

Making it cheaper

Two adjustments could significantly reduce the cost by about 30%. Thinning the walls to 0.2mm from 0.4mm and reducing the height by 5mm.